Price 1000000 आईएनआर/ Unit

MOQ : 01 Unit

Specification

- कवरेज एरिया

- 20 – 50 sqm

- विशेषताएँ

- Automatic Preform Loader, Touch Screen Control, Mold Change Alert

- फिल्ट्रेशन प्रॉपर्टी

- HEPA Air Filtration

- पावर सोर्स

- Electric

- टेक्नोलॉजी

- Microprocessor Controlled

- सतह की फ़िनिश

- Powder Coated

- फ़्रिक्वेंसी

- 50/60 Hz

- माउंटिंग टाइप

- Horizontal

- एक्सेसरीज़

- Conveyor, Auto Loader, Preform Holder, Cooling System

- शेप

- Rectangular

- ऑटोमेशन ग्रेड

- Fully Automatic

- एप्लीकेशन

- Industrial Bottle Manufacturing

- ऊर्जा दक्षता रेटिंग

- A++

- एयर फ्लो क्षमता

- 1.2 – 2.5 m³/min

- शोर का स्तर

- < 75 dB(A)

- मोटर स्पीड

- 1440 RPM

- आर्द्रता सीमा

- 10 – 90% RH

- मटेरियल

- टाइप करें

- पावर

- 15 kW

- वोल्टेज

- 380 V / 415 V

- क्षमता

- 1200 – 2200 bottles/hour

- इंस्टालेशन टाइप

- उपयोग

- फंक्शन

- Weight

- Approx. 1800 kg

- Material Feeding System

- Automatic Preform Feeding & Loading Unit

- Mould Material

- High Strength Aluminium Alloy

- Bottle Volume Range

- 200 ml – 2 L

- Number of Cavities

- 2 cavity / 4 cavity (optional)

- Cooling System

- Integrated Water Chiller Compatible

- Safety Features

- Emergency Stop, Overload Protection, Safety Guard Door Switches

- Air Compressor Requirement

- Minimum 8 Bar, 1.5 m³/min

- Operator Interface

- Touch Panel HMI

- Dimension (L x W x H)

- 3200 mm x 1100 mm x 2100 mm

- Heating System

- Infrared Preform Heating

- Cycle Time

- 6 – 9 seconds per cycle

Trade Information

- Minimum Order Quantity

- 01 Unit

- भुगतान की शर्तें

- मुख्य निर्यात बाजार

- मुख्य घरेलू बाज़ार

About

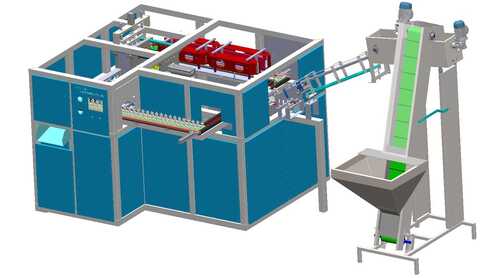

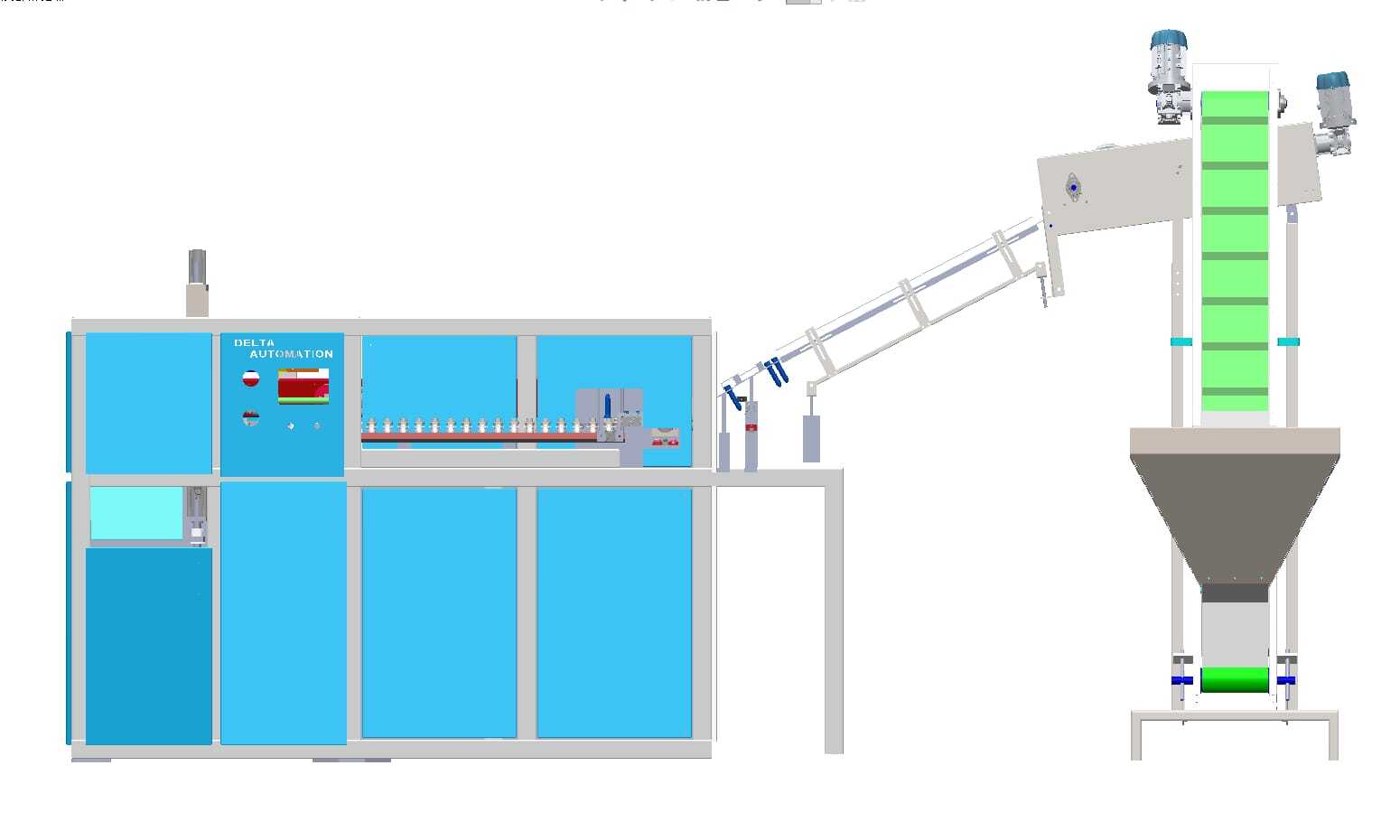

Grab the wondrous, world-class DELTA AUTOMATION PET Stretch Blow Moulding Machine with Auto Loader-a featured best-seller in industrial bottle manufacturing. With options for 2 or 4 cavities, this crackerjack machine produces 1200 to 2200 bottles per hour, handling volumes from 200 ml to 2 L. It's loaded with cutting-edge features like infrared preform heating, HEPA air filtration, and an automatic preform feeding system. Crafted from high-strength materials and powered by a robust 15 kW motor, it guarantees maximum efficiency, reliability, and safety with every cycle.

Exceptional Features & Professional Applications

The DELTA AUTOMATION PET Stretch Blow Moulding Machine boasts high-speed automation, mold change alert, touch screen controls, and integrated HEPA air filtration. Designed for industrial-scale plastic bottle production, it ensures consistent quality for beverage, pharmaceutical, and packaging industries. Used as a reliable solution for efficient PET bottle manufacturing, its automatic preform loader and conveyor accessories set the standard for contemporary bottle-making processes.

Sample Policy & Shipping Information

We offer a flexible sample policy and competitive list price for the DELTA AUTOMATION machine. Shipments are meticulously packed for secure transit from designated FOB ports. Each shipped good is wrapped using premium materials to avoid damage, and detailed packaging lists accompany every order. Consignments are dispatched promptly, ensuring the machine reaches you in perfect condition, while all shipping and packaging details are transparently communicated to streamline your purchase experience.

Exceptional Features & Professional Applications

The DELTA AUTOMATION PET Stretch Blow Moulding Machine boasts high-speed automation, mold change alert, touch screen controls, and integrated HEPA air filtration. Designed for industrial-scale plastic bottle production, it ensures consistent quality for beverage, pharmaceutical, and packaging industries. Used as a reliable solution for efficient PET bottle manufacturing, its automatic preform loader and conveyor accessories set the standard for contemporary bottle-making processes.

Sample Policy & Shipping Information

We offer a flexible sample policy and competitive list price for the DELTA AUTOMATION machine. Shipments are meticulously packed for secure transit from designated FOB ports. Each shipped good is wrapped using premium materials to avoid damage, and detailed packaging lists accompany every order. Consignments are dispatched promptly, ensuring the machine reaches you in perfect condition, while all shipping and packaging details are transparently communicated to streamline your purchase experience.

FAQ's of DELTA AUTOMATION PET STRECH BLOW MOULDING MACHINE WITH AUTO LOADER:

Q: How does the automatic preform loading system work?

A: The automatic preform feeding and loading unit efficiently supplies preforms to the heating section, significantly reducing manual effort and increasing production speed.Q: What is the typical process for operating this PET Stretch Blow Moulding Machine?

A: Operators simply set desired parameters via the touch panel HMI, load preforms into the feeder, and supervise production as the machine automatically heats, stretches, and moulds PET bottles at high speed.Q: When should the integrated cooling system be used?

A: The integrated water chiller-compatible cooling system runs during each cycle, helping maintain optimal mould temperature and ensuring consistent bottle quality.Q: Where is the DELTA AUTOMATION PET Stretch Blow Moulding Machine installed?

A: This machine is floor-mounted, making it suitable for industrial manufacturing facilities requiring robust PET bottle production capabilities.Q: What are the main benefits of using this machine for bottle manufacturing?

A: Users enjoy world-class energy efficiency, rapid cycle times, reduced labor input, advanced safety features, and reliable performance for medium to large-scale PET bottle output.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in केंद्रीकृत एसी एवं आर्द्रीकरण संयंत्र Category

केंद्रीकृत एसी एवं आर्द्रीकरण संयंत्र

पावर सोर्स : Electric

मटेरियल : ,

उपयोग : ,

शेप : Rectangular/Modular Units

माप की इकाई : यूनिट/यूनिट

एप्लीकेशन : Textile Mills, Pharma, Hospitals, Cleanroom, Commercial Buildings

हम आंध्र प्रदेश, कर्नाटक, केरल, पुडुचेरी, तमिलनाडु, ओडिशा, तेलंगाना में ही कारोबार कर रहे हैं।

जननी एंटरप्राइजेज, चेन्नई

122, 6 स्ट्रीट, ननबर्गल नगर

पूनामल्ले, चेन्नई - 600 056.

फोन: + (91) - (44) - 4555 8107

मोबाइल: + (91) -90470

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें