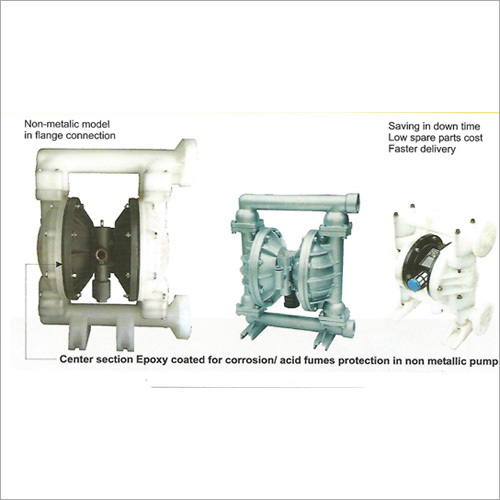

Air Operated Double Diaphragm Pump

Price 45000 INR/ Set

MOQ : 1 Set

Air Operated Double Diaphragm Pump Specification

- Material

- Aluminum Alloy

- Water Content

- Max 98%

- Central Distance

- 160 mm

- Working Pressure

- 0.2 0.7 MPa

- Rough Weight

- 8.5 kg

- Thermal Pressure

- Max 80C

- Dimension (L*W*H)

- 265 x 185 x 310 mm

- Advantage

- Corrosion resistant, easy to install and maintain, dry running capability, suitable for viscous fluids

- Noise Level

- <70 dB

- Max Flow Rate

- 160 L/min

- Application

- Chemical transfer, water treatment, food processing, paint & coatings, oil & gas

- Liquid Inlet/Outlet Size

- 1 inch BSP/NPT

- Max Particle Size

- 2.5 mm

- Installation

- Portable, skid mounting available

- Air Inlet Size

- 1/2 inch NPT

- Air Consumption

- 0.31.0 m/min

- Pump Type

- Air Operated Double Diaphragm (AODD) Pump

- Body Material Options

- Aluminum, Cast Iron, Stainless Steel (304/316), Polypropylene, PVDF

- Diaphragm Material

- PTFE, Santoprene, Nitrile (Buna-N), EPDM

- Max Suction Lift (Dry/Wet)

- 5 m (dry), 7 m (wet)

Air Operated Double Diaphragm Pump Trade Information

- Minimum Order Quantity

- 1 Set

- Main Domestic Market

- All India

About Air Operated Double Diaphragm Pump

Air Operated Double Diaphragm Pump allow you to handle different fluids with just one device. All double diaphragm pump models come with a choice of five different piping configurations to suit your needs. It also creates vacuum pump out systems with double diaphragm technology. Air Operated Double Diaphragm Pump helps in allowing facilities to have their own vac system without having to rely on a standard vac truck service. This pump is very easy to install as well as simple to use.

Robust and Versatile Fluid Handling

Engineered for efficiency, the AODD pump combines rugged construction with adaptability to a wide variety of process fluids. Whether dealing with corrosive chemicals, viscous solutions, or solids up to 2.5 mm, this pump meets the fluid management needs of diverse industries from food & beverage to oil & gas.

Designed for Safety, Efficiency, and Ease of Use

Operating at less than 70 dB, the pump ensures a quieter work environment. Its simple installation, portable design, and compatibility with both dry and wet suction lifts make it suitable for a range of plant layouts. Skid mounting options offer further flexibility for stationary setups.

FAQs of Air Operated Double Diaphragm Pump:

Q: How does the Air Operated Double Diaphragm (AODD) Pump function?

A: The AODD pump operates using compressed air as its driving force. Air alternately fills and exhausts chambers, flexing the diaphragms to draw fluid in and expel it through the outlet, ensuring gentle handling of fluids, including those containing solids.Q: What types of fluids and applications is this pump suitable for?

A: The pump is designed for chemical transfer, water treatment, food processing, paint and coatings, and oil & gas industries. It handles fluids with high water content (up to 98%), viscous or abrasive materials, and allows particles up to 2.5 mm in size, thanks to its robust construction and versatile diaphragm options.Q: Where can I install an AODD pump, and is it portable?

A: This pump is engineered for portability and can be installed in a wide range of locations. It comes with options for skid mounting for permanent setups, making it suitable for both mobile and stationary applications in industrial environments across India.Q: What are the benefits of the diaphragm and body material choices?

A: Multiple diaphragm materials (PTFE, Santoprene, Nitrile, EPDM) let you select the best chemical compatibility for your fluids, while body material options (Aluminum, Cast Iron, Stainless Steel, Polypropylene, PVDF) enhance durability and resistance to corrosion, extending service life and reliability.Q: How easy is the pump to maintain and operate?

A: The pump is designed for straightforward installation and maintenance. Its modular design and accessible components facilitate routine servicing, reducing downtime. Dry running capability and low air consumption also contribute to operational efficiency.Q: What operational conditions should be considered during use?

A: The pump operates optimally at air pressures of 0.20.7 MPa and can handle temperatures up to 80C. It delivers a maximum flow rate of 160 L/min with variable air consumption, providing flexibility according to application needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

We are dealing in Andhra Pradesh, Karnataka, Kerala, Puducherry, Tamil Nadu, Odisha, Telangana only.

JANANI ENTERPRISES, CHENNAI

122, 6th Street, Nanbargal Nagar

Poonamalle,

Chennai - 600 056.

Phone: +(91)-(44)- 4555 8107

Mobile: +(91)-90470 25249 / 98400 25243

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS