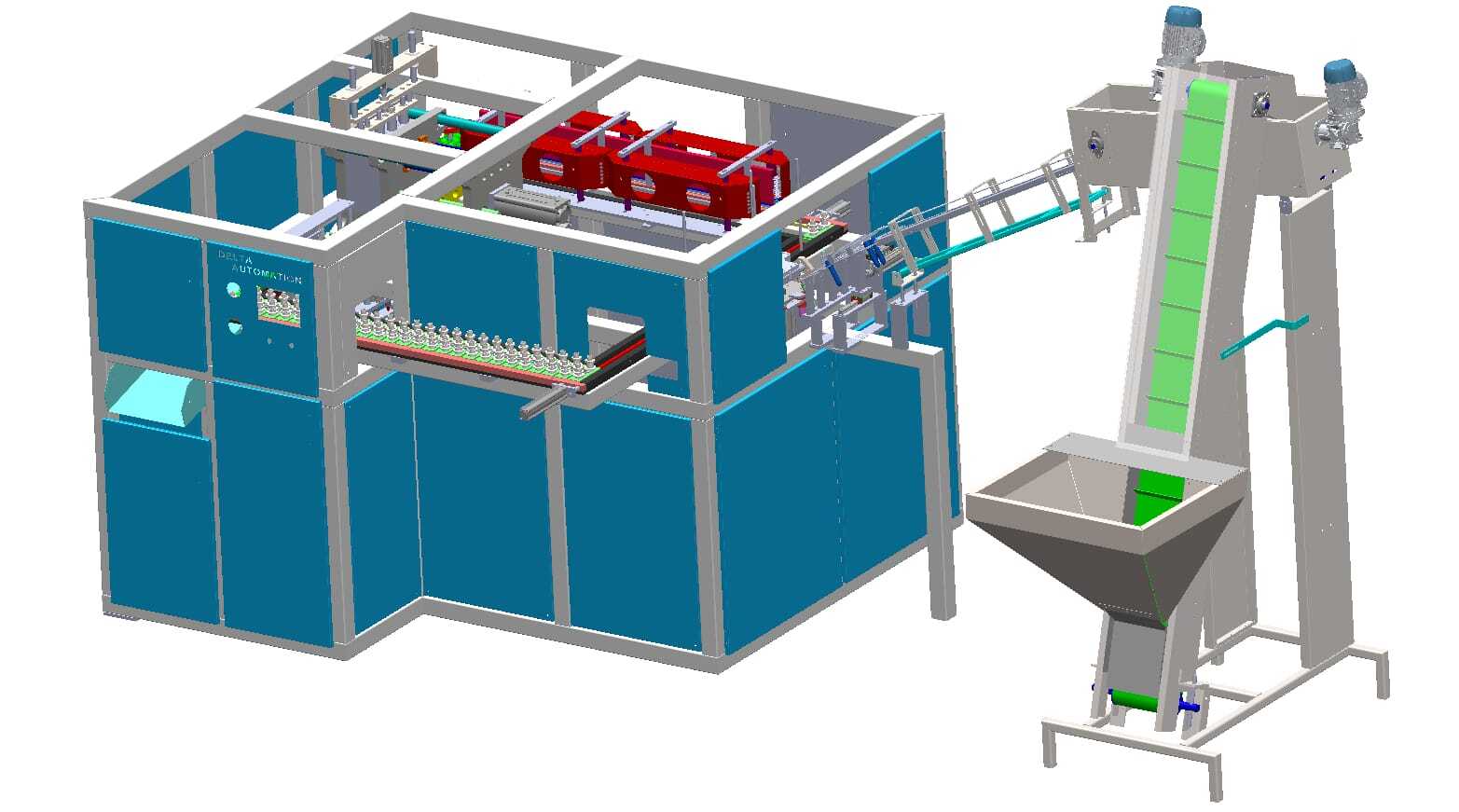

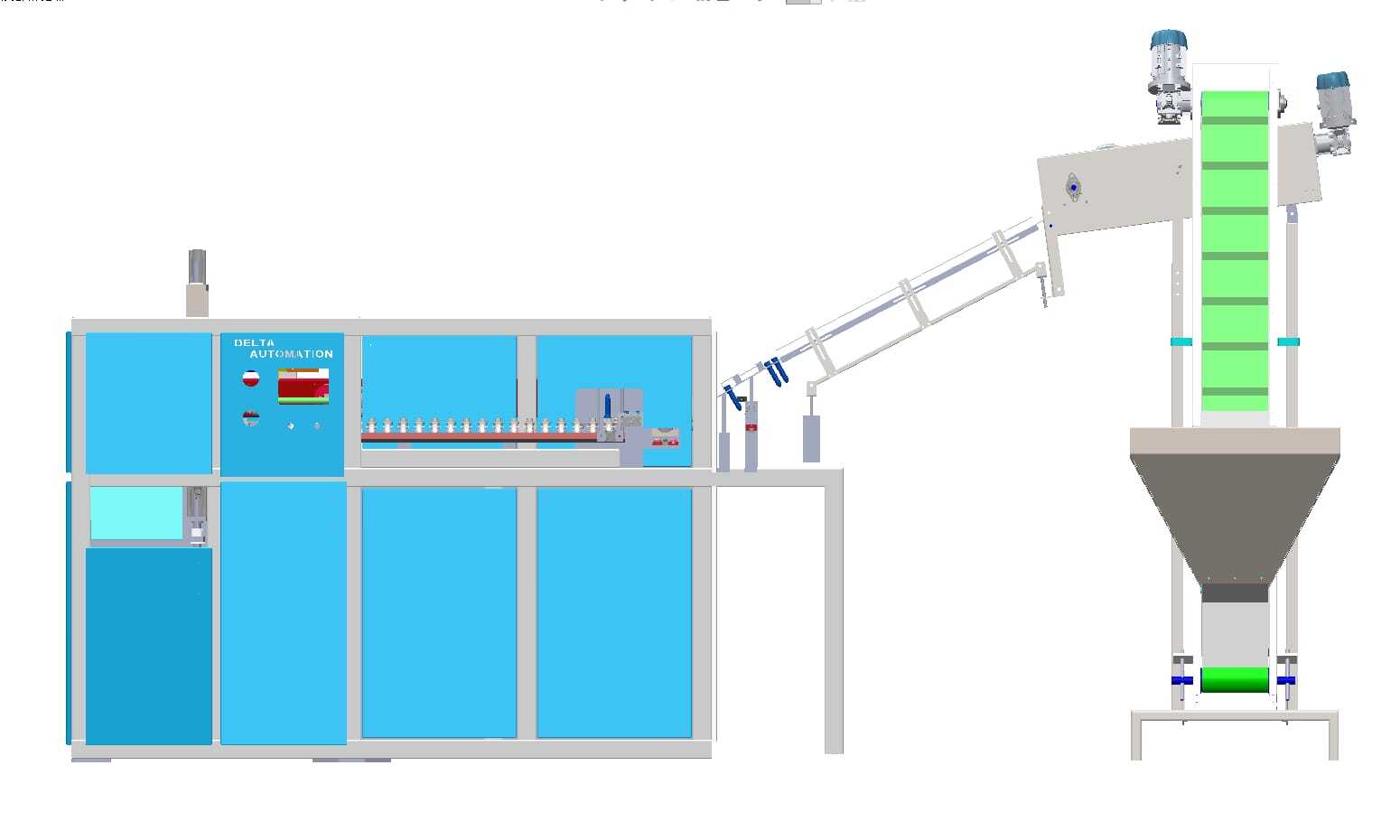

Pet Blow Moulding

Price 1100000 INR/ Piece

MOQ : 01 Piece

Pet Blow Moulding Specification

- Mould Material

- Special Alloy Steel

- Blowing Pressure

- 18-40 bar

- Material

- PET (Polyethylene Terephthalate)

- Neck Diameter Range

- 18mm to 120mm

- Product Name

- Pet Blow Moulding

- Application

- Bottle manufacturing, Jar manufacturing

- Heating Method

- Infrared

- Mould Cavity

- Single / Multi Cavity

- Type

- Blow Moulding Machine

- Production Capacity

- Up to 1200 bottles/hour (varies by model)

- Bottle Capacity Range

- 200ml to 5L

- Driven Type

- Electric

- Body Material

- Mild Steel / Stainless Steel

- Automation Grade

- Semi Automatic / Automatic

- Power Consumption

- Approximately 5 kW to 15 kW

About Pet Blow Moulding

The Pet Blow Moulding machine stands as a best-seller and a bargain for bottle and jar manufacturing, acclaimed for its superb precision and durable construction. Favored for its semi-automatic or automatic operation and varying production capacity-up to 1200 bottles per hour-this sought-after solution is engineered for efficiency. It supports bottle sizes ranging from 200ml to 5L with diverse neck diameters, while the wondrous use of infrared heating and special alloy steel moulds guarantees longevity. Customers have left favorable reviews, praising its consistent performance and versatility.

Innovative Features for Enhanced Performance

Pet Blow Moulding machines boast wondrous extra features, such as customizable cavities for diverse applications, robust mild steel or stainless steel bodies for long life, and advanced infrared heating for energy-efficient moulding. Designed for both bottle and jar production with easy-to-use controls, it suits a variety of application surfaces, offering reliability for large-scale and bespoke manufacturing. Its semi-automatic or automatic operation adapts seamlessly to the needs of modern production environments.

Domestic Presence, Global Reach, Fast Delivery

As a major manufacturer, service provider, and supplier in India, Pet Blow Moulding caters to the domestic market while maintaining a robust international presence, regularly exchanging expertise with clients in key export markets. The company ensures quick dispatch and offers favorable delivery times for all orders, both within India and abroad. Customers appreciate the prompt charge handling and efficient after-sales support, making every transaction smooth and dependable.

Innovative Features for Enhanced Performance

Pet Blow Moulding machines boast wondrous extra features, such as customizable cavities for diverse applications, robust mild steel or stainless steel bodies for long life, and advanced infrared heating for energy-efficient moulding. Designed for both bottle and jar production with easy-to-use controls, it suits a variety of application surfaces, offering reliability for large-scale and bespoke manufacturing. Its semi-automatic or automatic operation adapts seamlessly to the needs of modern production environments.

Domestic Presence, Global Reach, Fast Delivery

As a major manufacturer, service provider, and supplier in India, Pet Blow Moulding caters to the domestic market while maintaining a robust international presence, regularly exchanging expertise with clients in key export markets. The company ensures quick dispatch and offers favorable delivery times for all orders, both within India and abroad. Customers appreciate the prompt charge handling and efficient after-sales support, making every transaction smooth and dependable.

FAQ's of Pet Blow Moulding:

Q: How does the Pet Blow Moulding machine adjust to different bottle sizes and neck diameters?

A: The machine offers versatile mould cavity options and supports neck diameters ranging from 18mm to 120mm, allowing operators to easily switch configurations to accommodate bottle sizes from 200ml to 5L for diverse manufacturing requirements.Q: What is the process for using this blow moulding machine?

A: Simply load the PET preform and select your mould settings. The infrared heating system warms the preform before high-pressure air is used for moulding, followed by coolant circulation to solidify the product-ensuring efficient and reliable results.Q: When can I expect delivery after placing an order?

A: Our efficient order handling and quick dispatch processes ensure that production and delivery are completed in a timely manner, with estimated delivery times communicated at the point of purchase. Domestic orders are typically fulfilled within a short span.Q: Where can this machine be used?

A: The Pet Blow Moulding machine is ideal for use in bottling plants, packaging industries, and manufacturing facilities that require precise and scalable production of PET bottles and jars.Q: What are the benefits of its infrared heating method?

A: Infrared heating provides uniform temperature application, which not only improves energy efficiency but also enhances the quality and consistency of each moulded bottle or jar.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Plastic Components Category

We are dealing in Andhra Pradesh, Karnataka, Kerala, Puducherry, Tamil Nadu, Odisha, Telangana only.

JANANI ENTERPRISES, CHENNAI

122, 6th Street, Nanbargal Nagar

Poonamalle,

Chennai - 600 056.

Phone: +(91)-(44)- 4555 8107

Mobile: +(91)-90470 25249 / 98400 25243

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS