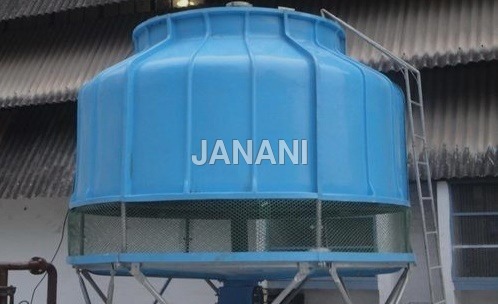

PVC Three Phase Fluidized Bed Cooling Tower

PVC Three Phase Fluidized Bed Cooling Tower Specification

- Material

- PVC with FRP Reinforcement

- Application

- Industrial process cooling, HVAC, Power Plants, Chemical Plants

- Motor

- High-efficiency, TEFC, 3 Phase Induction Motor

- Air Flow

- 12000-25000 m/h (depending on model)

- Refrigerating Capacity

- 30 TR 150 TR (varies by model)

- Condition

- New

- Type

- Fluidized Bed Cooling Tower

- Dimension (L*W*H)

- Customizable (Standard: 2000mm 1500mm 2800mm and up)

- Power Supply

- 3 Phase, 50Hz

- Voltage

- 380V / 415V

- Cooling Type

- Closed Circuit / Fluidized Bed

- Nozzle Material

- PVC

- Cooling Coil Material

- Galvanized Steel / SS304

- Water Flowing Rate

- 50-250 m/h

- Water Pump Motor

- Included, matched to system requirement

- Noise Control

- Low noise design, below 68 dB(A) at 1 meter

- Drift Loss

- Less than 0.002% of circulating water flow

- Fan Blade Material

- FRP (Fibre Reinforced Plastic)

- Serviceability

- Easy Access for Maintenance

- Tower Body Finish

- UV-Protected, Rustproof Exterior

- Ambient Operating Temperature

- Up to 55°C

- Installation

- Skid Mounted, Ready-to-Install

- Mounting

- Floor Mounted with Anti-Vibration Supports

- Fill Type

- Honeycomb PVC Fills

- Control Panel

- IP55 Rated, Automatic

- Inlet/Outlet Connection

- Flanged, Corrosion Resistant

PVC Three Phase Fluidized Bed Cooling Tower Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 15 Days

About PVC Three Phase Fluidized Bed Cooling Tower

Versatile Applications & Advanced Features: Cooling Excellence

Our PVC Three Phase Fluidized Bed Cooling Tower stands out for its advanced FRP fan blades, closed circuit or fluidized bed design, and customizable dimensions. Additional features include IP55 automatic control panel, anti-vibration supports, and ready-to-install skid mounting. Suitable for industrial process cooling, HVAC systems, chemical and power plants, it is engineered for durability, efficiency, and easy maintenance. Embrace this adaptable solution where robust, corrosion-proof construction meets broad industrial application needs.

Domestic & Export Markets: Trusted Supply & Policies

We serve a superlative clientele both in the main domestic market of India and in key export markets worldwide. Stock ready for dispatch ensures shipment of goods at unmatched sale price, meeting urgent project needs efficiently. We provide flexible sample policies on request, making product assessment easy before large orders. Relied upon by manufacturers and service providers, our cooling towers are always available for prompt supply and seamless global shipping.

FAQs of PVC Three Phase Fluidized Bed Cooling Tower:

Q: How does the fluidized bed cooling process in this tower benefit industrial applications?

A: The fluidized bed cooling process enhances heat transfer efficiency, ensuring rapid and uniform cooling for industrial process systems, resulting in improved energy savings and operational reliability.Q: What are the main usage scenarios for the PVC Three Phase Fluidized Bed Cooling Tower?

A: This cooling tower is ideal for use in industrial process cooling, HVAC applications, power plants, and chemical plants where corrosion resistance and efficient heat exchange are critical.Q: Where is the PVC Three Phase Fluidized Bed Cooling Tower most commonly installed?

A: These towers are typically floor-mounted on industrial sites, manufacturing facilities, and plants, thanks to their robust construction and easy maintenance access.Q: What makes the maintenance process of this cooling tower particularly user-friendly?

A: The system features easy access panels and anti-vibration supports, allowing for routine inspections, quick servicing, and efficient replacement of maintenance parts without disrupting overall operation.Q: How does the product ensure low environmental impact during usage?

A: With less than 0.002% drift loss and a low-noise design under 68 dB(A), the cooling tower minimizes water wastage and sound pollution, providing a more environmentally responsible cooling solution.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cooling Towers Category

Counter Flow PVC Fills Packed Cooling Tower

Price Range 50000.00 - 100000.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Condition : New

Material : Other , PVC (Polyvinyl Chloride)

Type : Counter Flow PVC Fills

Fillless Cooling Towers

Price Range 50000.00 - 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Material : Metal

Type : Cooling Towers

Color : Blue

Induced Draft Cooling Tower

Price Range 50000.00 - 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Material : FRP

Type : Cooling Tower

Color : Blue

Package Type Cooling Towers

Price Range 50000.00 - 100000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Material : Metal

Type : Cooling Towers

Color : Sea Green

We are dealing in Andhra Pradesh, Karnataka, Kerala, Puducherry, Tamil Nadu, Odisha, Telangana only.

JANANI ENTERPRISES, CHENNAI

122, 6th Street, Nanbargal Nagar

Poonamalle,

Chennai - 600 056.

Phone: +(91)-(44)- 4555 8107

Mobile: +(91)-90470 25249 / 98400 25243

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS